Alloy 및 Temper의 이해

APR 04, 2015

CG Team, Specialties Sales

APR 04, 2015

CG Team, Specialties Sales

| Alloy |

|---|

| Alloy Series | Major Alooying Element(s) |

|---|---|

| 1xxx | 99.00 wt%min. AI |

| 2xxx | Cu (or Cu+Mg) |

| 3xxx | Min (or Min+Mg) |

| 4xxx | Si |

| 5xxx | Mg |

| 6xxx | Mg + Si |

| 7xxx | Zn + Mg (or Zn+Mg+Cu) |

| 8xxx | Other elements (e.g.,Li, Fe+si > 1.0%) |

각국의 Standards KS, JIS, AA, BS, DIN etc.

-> ASTM B209-10

KS D6701 2002

JIS H4000_2006

EN 485-2 2008

* ASTMI(American Society for Testing and Materials)

| Alloy |

|---|

| 합금 비율 또는 주요 합금 원소 | 합금 번호 | 적용 대상 |

|---|---|---|

| 순도 99.00% 알루미늄 | 1XXX | 호일, 인쇄판, 전도체 |

| 구리 | 2XXX | 항공소재 |

| 망간 | 3XXX | 알루미늄캔, 건축용 판재, 일반재, 핀재(fin) |

| 규소 | 4XXX | 브래이짐/클래딤재 |

| 마그네슘 | 5XXX | 알루미늄캔, 일반재, 자동차 |

| 마그네슘 및 규소 | 6XXX | 자동차, 일반재 |

| 아연 | 7XXX | 항공소재, 핀재 |

| 기타 원소 | 8XXX | 호일(Fe), 항공소재(Li) |

| 미사용 | 9XXX | |

| ex) 1XXX 첫 번째 숫자는 주요 합금원소의 합금 번호에 의해 분류 두번째 숫자는 합금에 대한 변경이나 불순물 한계(1xxx)를 표시 세번째 및 네번째 숫자는 특정 합금을 표시하거나 1xxx 합금의 경우 알루미늄 최소 함량을 표시 |

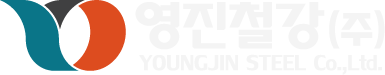

주요 합금원소에 기초한 합금 분류체계는 알루미늄협회에 의해 제정되었다. Zn, Mg, Cu, Si, Mn은 알루미늄 산업에서 하용되는 합금 원소의 대부분을 차지한다. |

|

| Alloy |

|---|

| Temper |

|---|

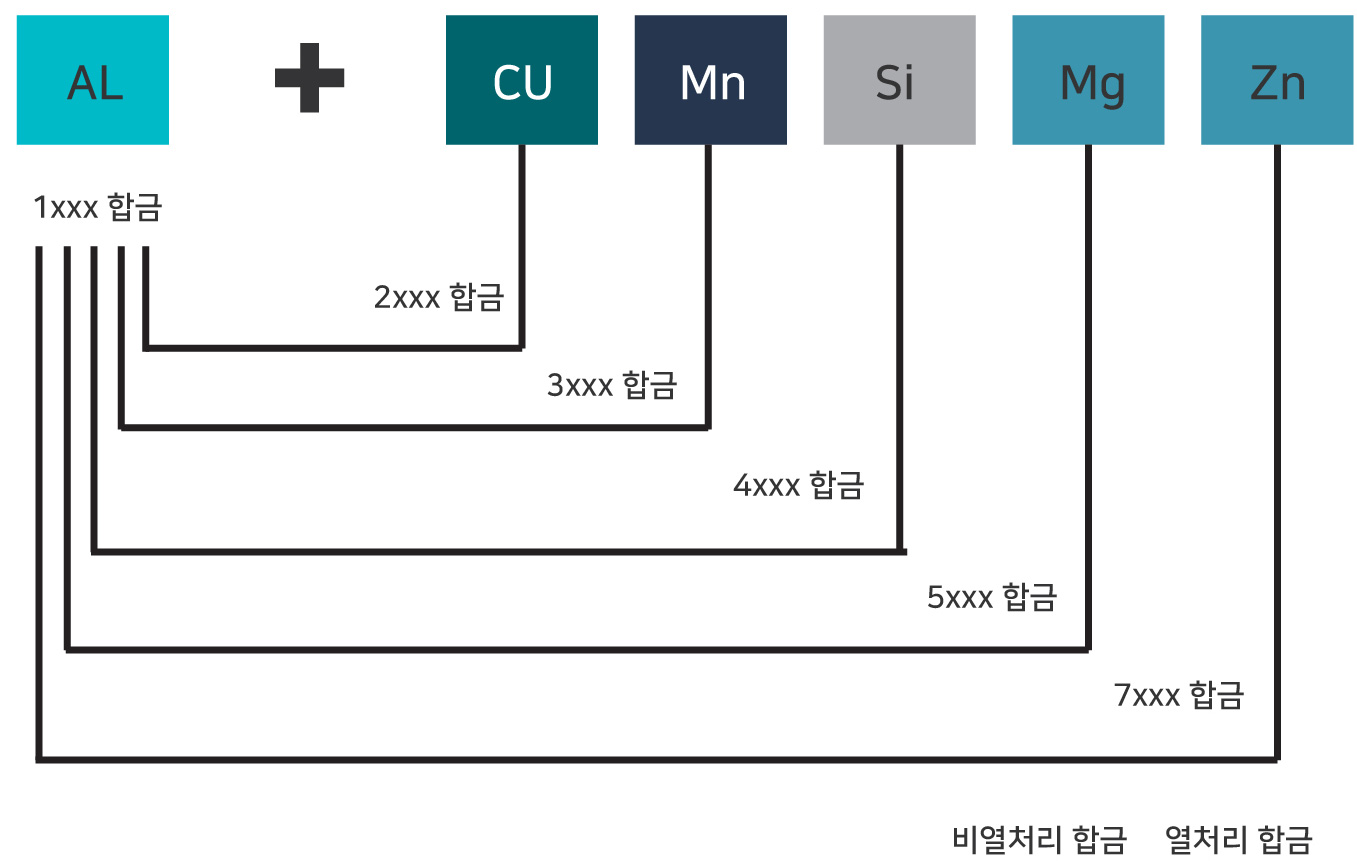

| ● F | As fabricated Not controlles; State after cold or hot rolling |

| ● O | Annealed To obtain the softest state |

| ● H | Strain-Hardened H1 Strain-hardened only H2 Strain-hardened and partial annealed H3 Strain hardened and stabilized (if age softening at room temp.) H4 Plus after process like coating |

| ● T | Tempering (Heat treat) T1 T4 T6 / T651 |

| Temper |

|---|

| ▶기계적 성질 비교표 (알루미늄 판재 및 아연 도금 강판) |

|---|

| * AL-Mg 5000계 합금은 해수 및 공업지대의 오염에 강합니다. |

|---|

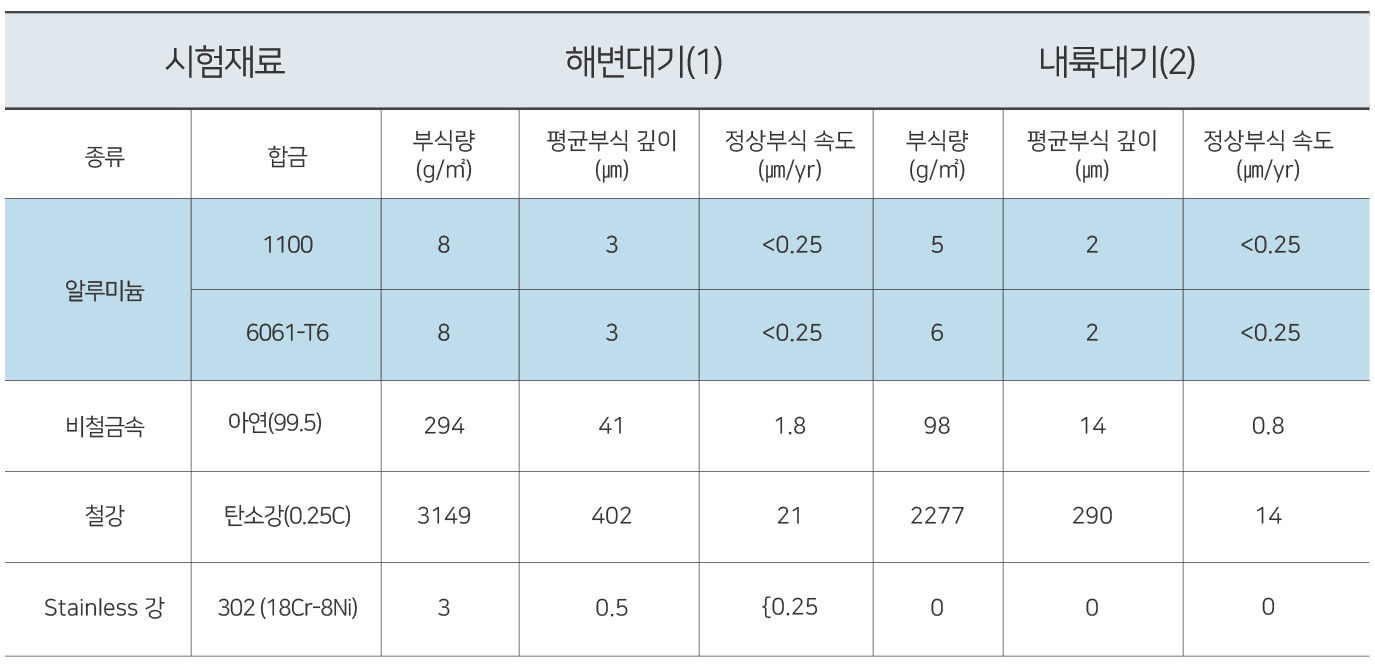

| ▶자연환경에 있어서 내식성 시험 (대기노출 시험 16년의 결과) |

|---|

| (1) 노출장소 : Limon Bay (Panama 운하지대) (2) 노출장소 : Miraflores Locks (Panama 운하지대) 해안에서 8km |

|---|